XeF2二氟化氙气氛刻蚀

XeF2气相刻蚀是一种强大的微电子制造刻蚀技术。使用XeF2气体进行硅刻蚀,硅表面与XeF2反应,生成SiF4分子。这种非等离子刻蚀工艺,实现了对其它材料高的刻蚀选择比,如光刻胶、金属(Al、Ni、Cr)和化合物半导体(GaAs、ZnO、PZT)。

设备用途

这种工艺主要用来对氧化硅的同向性刻蚀。这种刻蚀工艺是完全干燥的,去除了传统湿法刻蚀过程中的粘附问题。对于释放过程中容易粘附的结构,用于制作MEMS悬臂梁,比如mems麦克风,加速度计等产品非常适用。

As a dry process, memsstar’s XERIC XeF2 etching eliminates stiction in a single process. The patented memsstar XERIC sacrificial vapor release XeF2 (SVR-Xe) process is highly selective to a range of materials including aluminum, photoresist, silicon nitride and silicon dioxide. And, since it is isotropic, large undercuts of structures can be performed with no degradation in etch rate. The XeF2 process is capable of etching a wide range of films including silicon (in all forms), molybdenum, germanium and tungsten.

Sacrificial Layers:

Polysilicon, amorphous silicon, single crystal silicon, molybdenum, germanium, tanatalum, tungsten

Protective Layers:

Stoichiometric PECVD nitride, silicon dioxide, thermal oxide, TEOS, quarts, PECVD oxide, spin-on oxide, Si-rich LPCVD nitride

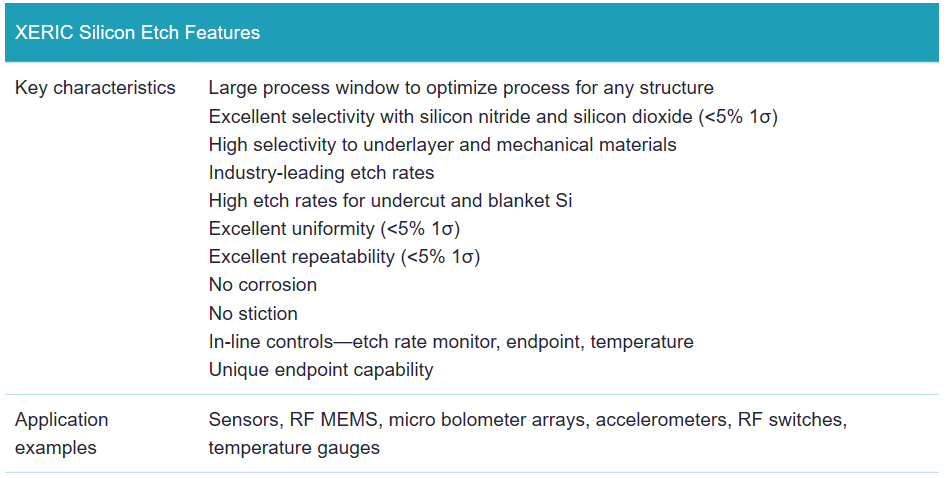

memsstar’s XERIC XeF2 etch offers industry-leading etch rates and our single wafer processing guarantees excellent repeatability and wide process windows to maximize performance and yield. A controlled vaporization system is used to deliver precise amounts of etch gas into a single-wafer vacuum chamber, which has a full range of process controls. The advantages of the XERIC process can be clearly evidenced in continuous-flow mode using memsstar’s CCFT technique. Unique process controls deliver tunable etch rates, uniformity and selectivity, with endpoint capability and thermal control of the wafer during etch.

系统构成

技术指标

1. 释放良率,无黏附的干法释放,Mems结构100%完全释放

2. 刻蚀速率,悬臂结构大于10um/min,空白暴露硅大于0.5um/min

3. 片内均匀性≤5% 1s

4. 片间均匀性≤5% 1s

5. 选择比对PECVD氮化硅>750:1